ZAMACAST'S

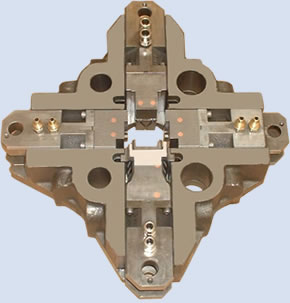

TECHNOLOGY AT 4 INDIPENDENT SLIDES OFFERS THE FOLLOWING BENEFITS:

Speed: die-casting

machines are pneumatic and completely automatic. They produce at high

speed, (up to 50 cycles per minute) and this allows great production

volumes in short time.

Precision: Moulds are smaller than traditional one, they can be

worked with much accuracy and precision and their maintenance is simpler

and more efficient.

Repeatability: quicker production makes possible the construction

of moulds with a smaller number of cavities, keeping prices competitive.

This reduces consistently the dimensional variation.

Freedom of project: our own four independent slides technology allow

complex shapes without building expensive moulds. Moreover, in many

cases, it's possible to eject the parts without any mark of pin ejectors.

Flexibility: the machines used to produce are designed and built

internally. This allows specific solutions to particular needs; not

only the mould, but also the machine can be built in function of the

final product to be realised.

Economically: the above mentioned characteristics brings to an economic

benefits for the Customer, both for the reduction of the cost and the

increase of the product performance.

| Download Zamacast's brochure in English pdf 423 Kb |